Ten most significant advances in 4x4s

1. Modern turbo-diesel engines

What sets today’s 4x4s most apart from those of not just 60 years but those of even 20 years ago, is the modern turbo-diesel engine and its outstanding trifecta of performance, economy and refinement. This revolution in engine technology was born 30 years ago in Europe off the back of EU government policy that favoured diesel-engine development over petrol engines due to a diesel’s lower production of carbon dioxide, so-called greenhouse gas. Yes, there was a time when diesel engines were at the forefront of being ‘green’.

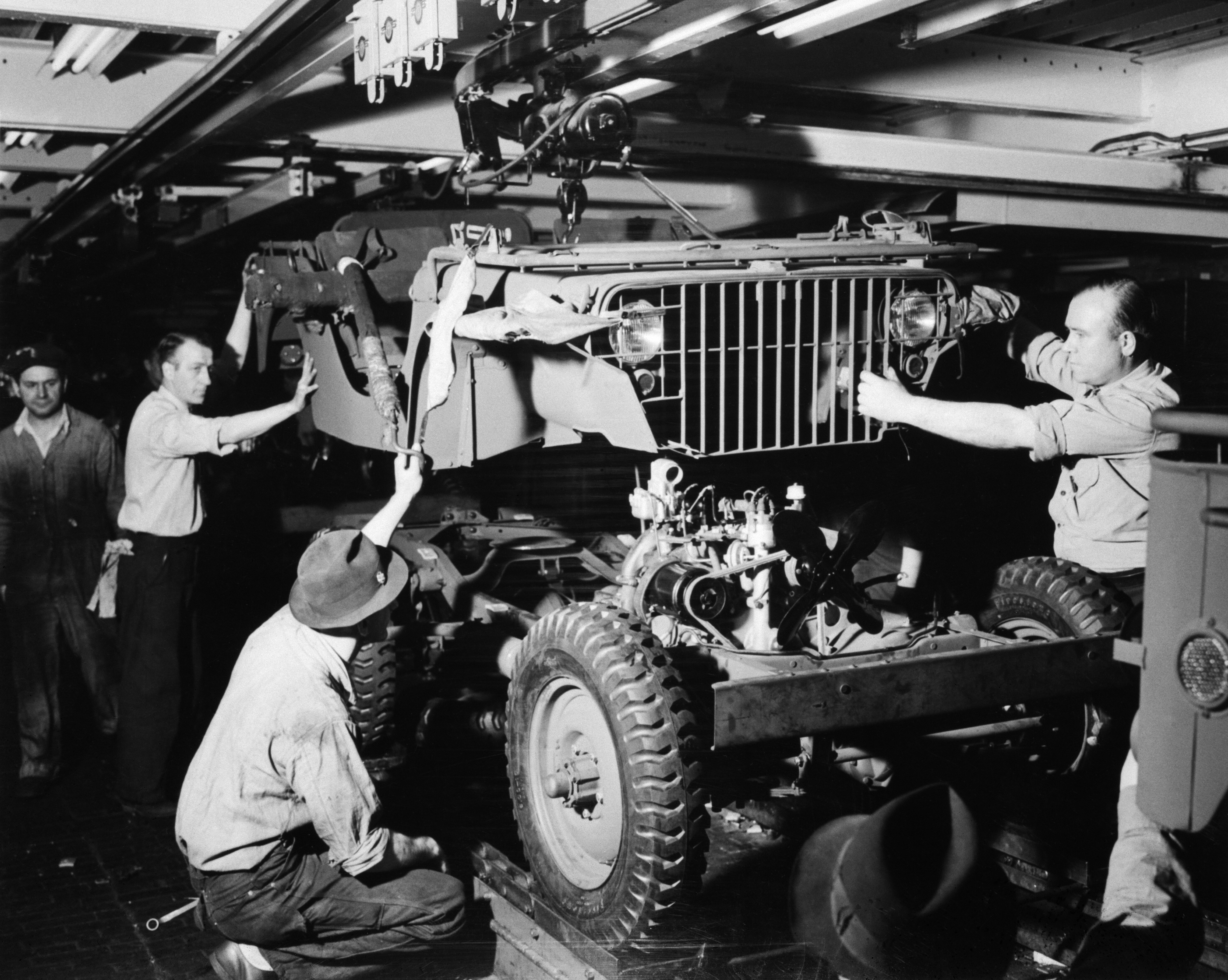

27

4x4s have come a long way since WWII-era vehicles

Before the diesel revolution arrived, if you wanted decent performance in your 4×4 you had a petrol V8 or a big (plus 4.0-litre) petrol six. If you wanted economy, you had a diesel. Trouble was the big petrol motors were thirsty and the diesels were dead sluggish if naturally aspirated and only modest performers if turbocharged, while the popular mid-sized petrol V6s of the time were excellent on neither count.

The new-tech diesels increasingly meant that you could have both performance and economy, as they were simply much better at extracting every last morsel of energy out of every drop of diesel fuel, thanks largely to very precise high-pressure common-rail diesel injection and evermore sophisticated turbocharger technology, including the use of multiple turbos.

27

You’ll now find Euro-inspired diesel tech in the new LC300

This revolution didn’t arrive all in one hit, but if there was one engine that signalled the bold and brave new world of performance diesels had arrived in Australia it was the 3.0-litre BMW straight-six that was offered in the then-new third generation Range Rover in 2002. That generation Range Rover also came with a modern quad-cam 48-valve 4.4-litre petrol V8 (also a BMW engine) and in give-and-take driving, the punchy ‘little’ diesel gave nothing away to the near 50 per cent bigger petrol V8. And after all these years, modern European-inspired diesel technology has migrated all the way to diesel-conservative Toyota, in the engine we see in the 300 Series.

2. Tyres

27

Modern 4x4s are spoilt for choice when it comes to tyres

Literally everything is riding on your tyres and you can count yourself lucky that you’re not riding these days on bias-ply (so-called cross-ply) tyres, especially ones with bar treads. Bar treads on a wet bitumen road? Easiest way to find the roadside ditch ever invented.

To tell the truth, any bias-ply tyre, even ones with a road pattern tread and on dry roads, weren’t great in terms of steering and handling satiety.

Radial construction, where the plies run 90-degrees bead to bead rather than diagonally, as is the case with bias-ply tyre, proved to be the answer; but while the radial tyres first appeared in 1948 (on the then-new Citroen 2CV courtesy of Michelin, Citroen’s owner at the time), the technology didn’t become widespread until 30 or more years later.

Off the back of the radial tyre came the light-truck radial tyre, which offers more robust construction than a passenger-car radial, obviously just what you want with a 4×4. Light-Truck (LT) radials can also run higher pressures to cope with heavier loads, which is also just what you want on a heavily laden touring 4×4.

27

All this would still probably come to little if we were still using bar-tread patterns for mixed on- and off-road driving, but instead we can now choose between an all-terrain tyre (AT) or a mud tyre, assuming of course you don’t want a road-pattern tyre. Better still you can choose your AT tyre based on your personal mix (50:50; 60:40; 80:20, etc.) of on- and off-road driving.

We can also be thankful that tyre manufacturers have come to the party when vehicle manufacturers have forsaken off-road practical wheel sizes (15- and 16-inch) for larger diameter wheels, purely for fashion reasons. Having a low-profile 20-inch tyre that is practical and effective off-road is indeed an engineering miracle given the inherent off-road disadvantage of having very little tyre sidewall.

Here’s a 4×4 tyre shopping tip: If you don’t want a Light Truck tyre on your 4×4 – if it was designed around a passenger-construction tyre (and there are some negatives in fitting an LT tyre) – but still want a reasonably robust all-terrain tyre, then all is not lost. The trick is in the speed-rating, and lower is better, which in effect means an R or S speed-rated tyre given typical availability.

3. Long-travel suspension

27

The best 4x4s of today would be nothing without long-travel suspension, not that every new 4×4 is similarly blessed. Long-travel suspension is where 4×4 ability starts, provided the design basics like ground clearance and effective engine power/gearing are covered.

The more suspension travel and therefore the more axle articulation you have, the easier things become as your tyres keep in firmer contact with the ground. Which means you’re less reliant on limited-slip diffs, diff locks and electronic traction aids and the like to keep things moving. The downside of long-travel suspension is excessive body lean when cornering on road, but more on that later.

27

The more suspension travel, the more axle articulation you have

The watershed moment in 4×4 suspension evolution came with the arrival of the Range Rover in 1970. With long-travel coil springs instead of leaf springs, the default suspension of the day as used with Series Land Rovers, LandCruiser 40s and Jeep CJs, both off-road ability and off-road comfort were taken to another level. It took a while for the typically engineering-conservative Japanese manufacturers to catch up, but they did with the Patrol GU in 1987 and the LandCruiser 80 in 1990.

The wheel-travel advantage offered by coil springs also brought a rethink of leaf-spring design. By using longer but thicker leaves, more travel can be engineered in to leaf springs without compromising load-carrying ability. The leaf springs on the current Hilux, Ranger and Amarok provide wheel travel and axle articulation that some coil-spring designs can’t match.

4. Full-time 4×4

27

Unlike other current mid-size pickups, the Mitsubishi Triton features full-time 4×4

The majority of new four-wheel drives today don’t have full-time 4×4, but that’s only because part-time 4×4 is a cheaper system to manufacture, which means a more attractive showroom price for the vehicle in question. And if most buyers are more than happy with part-time 4×4, then why bother with full-time 4×4?

Premium 4WDs – think LandCruiser, Range Rover, Grand Cherokee and the like – do have full-time 4×4 and for good reason. Compared to part-time 4×4 it brings considerable safety, convenience and drivability advantages. It’s simply a better way to drive.

The first Land Rover which arrived on the world stage in 1948 had full-time 4×4 of sorts, but the system was complex and dropped after three years in favour of part-time 4×4. Full-time 4×4 didn’t effectively reappear until 1970 – this time for good – with the debut of the original Range Rover. This pushed Jeep in 1972 to introduce full-time 4×4 on the Wagoneer, its premium model of the time, with Toyota eventually joining the party with its 80 Series in 1990. From there, full-time 4×4 has become more common and is even available on the Mitsubishi Triton, the least expensive of the mainstream utes. Cashed- p new Ford Ranger buyers will also be able to enjoy full-time 4×4 with the oon-to-arrive V6 Ranger, which may force Toyota’s hand with the next-generation Hilux. Toyota already has the parts needed in its Prado …

5. Electronic traction control

27

Ford Ranger keeps the front ETC active even ith the rear diff lock engaged

Electronic traction control (ETC) is standard on every new 4×4 and has been for a decade or so; although, there have been some slow adopters, most notably the LandCruiser 70 Series which has had it for only half that time and only then off the back of new-car safety laws. ETC didn’t become mandatory then, but electronic stability control (ESC) did and ETC is a relatively simple but necessary building-block tech for ESC.

The beauty of ETC is its simplicity as it doesn’t require any extra hardware once you have anti-lock brakes (ABS), which became increasingly standard fitment on cars and 4x4s through the 1970s and ’80s. Where ABS prevents a wheel from locking under brakes by automatically reducing the braking effort, ETC applies braking effort to stop a wheel from spinning under power. Once you have ABS, ETC only requires a simple electronic tweak and effectively transforms a standard open mechanical differential in to a drive-proportioning differential.

Not all ETC systems are created equal, though. First generation ETC systems were generally designed to prevent wheelspin on wet roads but still offered a game-changing benefit off road. Second- and third-generation ETC systems designed specifically for off-road use are even better again.

6. Lighting

27

Without a doubt, LEDs are now the pinnacle of automotive lighting

Despite driving at night amounting to only 25 per cent of driving for most people, 50 per cent of road accidents occur at night. And that’s with the good headlights and vehicle recognition lighting we have today.

You may be lucky to not have to drive at night, but most of us have to at times, so it’s handy to be able to see where you’re going! Driving outside of built-up areas, where there’s no street lightning, makes lighting even more important, as

every 4×4 driver knows. Hence the amount of money for aftermarket auxiliary lights that have been spent over the years!

27

There was a time when driving without auxiliary lighting on your 4×4 meant you were still largely driving in the dark. Things took a big step forward when halogen gas was added to tungsten filament bulbs to create so-called halogen headlights in the 1960s, the significant lighting revolution of the day.

Things got even better when High Intensity Discharge (HID) headlights using an electric arc between two electrodes in an inert gas (generally xenon) to do away with a filament altogether started to appear in the 1990s. Then hot on the heels of HID lights have come light-emitting diode (LED) headlights, which are brighter again, use less power and last longer. It’s seventh heaven now compared to tungsten-filament days.

7. Smart differentials

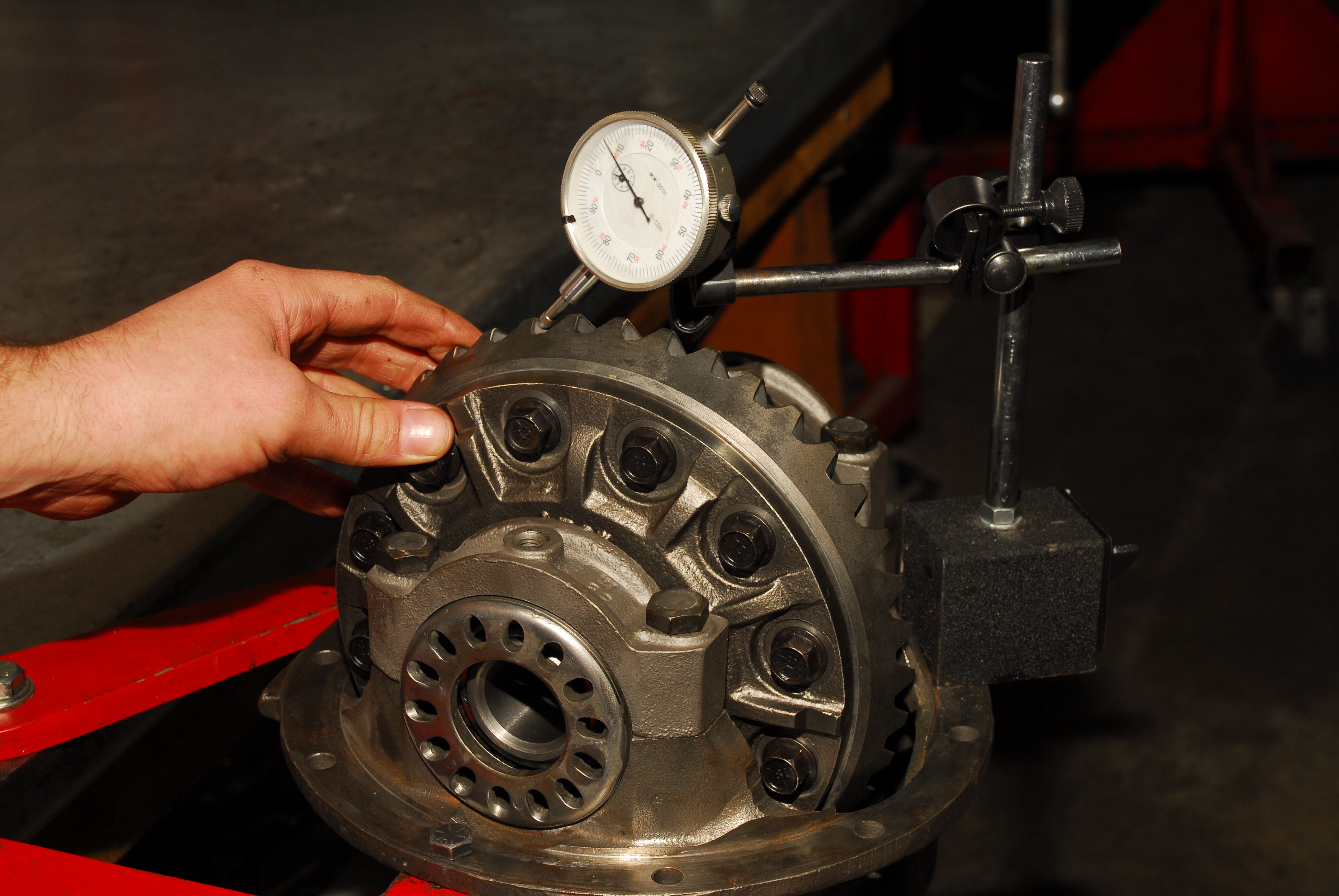

27

Differentials can be the make-or-break of a 4×4 once you have obvious design basics such as clearance, suspension travel and power/gearing covered. The issue here is a differential is exactly what you don’t want off-road but is essential for on-road driving.

Differentials, as the name suggests, allow the wheels on either side of an axle to turn at different speeds if need be. On road you need this just to be able to drive around corners given the inside wheel on either axle has to slow down (less distance to travel), while the outside wheel on the same axle has to speed up to cover the greater distance of its wider arc. This is the standard function of an open differential.

The trouble off-road is that an open diff feeds the power along the path of least resistance across an axle, so if either tyre on that axle loses traction, all the power will go that way and the wheel spins away uselessly.

27

In the Amarok, the driver doesn’t have to lock the centre diff, as that happens automatically when needed

So-called ‘smart’ or ‘E’ diffs address this problem by using an electronically controlled clutch to feed the power to the wheel(s) where it can be best used. The clutch responds to information from sensors that monitor wheel-speed, throttle application and the like and can work in a proactive way rather than just reactive.

Smart diffs are used in both rear cross-axle and centre inter-axle applications and can typically proportion the drive from a locked 50:50 to all or near all of the drive going to either axle in a centre inter-axle application or to either wheel in a cross-axle application.

8. Driver-switched diff locks

27

Driver-switched lockers have become common on mainstream 4x4s

Buy a new 4×4 ute today and you’ll most likely be buying one with a driver-switched lock for the rear differential. When you flick the switch, an electro-magnetic solenoid engages the differential lock, which means the diff effectively stops being a diff, which means neither wheel can spin by itself. If there’s wheelspin, it has to be both wheels together.

Driver-switched lockers have become common on new mainstream 4x4s during roughly the same time frame that electronic traction control has become standard on new 4x4s, and the way the two work together – or not work together – determines the quality of the outcome.

Driver-switched rear lockers that keep the front-axle ETC active when they are engaged do the best job – a very good job in fact – while those that cancel the ETC altogether when engaged provide more of a mixed outcome. They can still be an advantage, it just depends on both the exact driving situation – mud, sand, rocky climbs, etc. – and the vehicle in question. (Details on this with contemporary utes was covered recently in our ute buyer’s guide.)

9. Adaptive suspension

27

Adaptive suspension often comes in the form of height-adjustable air suspension.

Long-travel suspension (see #3 above) that is so essential to the making of a good 4×4 comes with an inherent problem: excessive body lean when cornering on road, with tight corners and higher speeds both being the aggravating factors. So-called anti- roll or sway bars help limit this on-road body lean but they also reduce axle articulation, which is not what you want off-road.

To avoid this compromise, various types of adaptive suspension systems have been aimed at minimising on-road body lean when cornering without being a compromise off-road. Land Rover’s Active Cornering Enhancement introduced on the Discovery II in 1998 was the first such technology and used pressure accumulators and hydraulic cylinders, triggered by two G-force sensors, to stiffen up the sway bars for on-road cornering, while also allowing them to relax for off-road driving. Toyota’s Kinetic Dynamic Suspension System, introduced in Australia on the 200 Series, did essentially the same thing but was simpler and didn’t use any electronic control, being purely hydro-mechanical. Electronic enhancement of KDSS would come later on the second-generation system fitted to the Prado 150 and the third system fitted to the 300 Series.

Nissan’s Y62 Patrol goes further by ditching the sway bars altogether and interconnecting the four hydraulic cylinders that control the wheel movement via two hydraulic accumulators. In that way, hydraulic fluid can be pumped from one corner of the vehicle to the other to either reduce on-road body lean or maximise off-road wheel travel.

Adaptive suspension that addresses the on-road/off-road design dilemma also comes in the form of height-adjustable air-spring suspension, typically but not exclusively found on 4x4s with fully independent suspension. This allows a low ride height and flatter handling on-road driving, yet can jack itself up to give excellent off-road clearance and maximum wheel travel.

10. Terrain-specific electronics

27

Electronic stability control (ESC) is now mandatory on all new 4x4s and automatically corrects a skid and helps prevent losing control on wet or slippery roads. First appearing some 30 years ago on passenger cars, it’s a proven lifesaver.

Trouble is off-road, where ESC can be a nuisance as it cuts engine power and/or applies one or more individual wheel brakes if the vehicle isn’t following its exact steered path, which easily happens in mud or soft sand. Cutting the power and/or applying the brakes is obviously a momentum killer, which is not what you want in either mud or soft sand.

To counter this, 4x4s have an ESC-off mode, which you activate via a switch or button. ESC-off mode is only available at low speeds (generally below 30km/h or so) and comes back on automatically once the vehicle speed increases above that limit.

A far better solution is to optimise the ETC and the ESC programming (among other things) to suit different types of off-road terrain. Land Rover initiated this with its Terrain Response on the Discovery 3 in 2004 and allowed the driver to switch from the standard road setting to ‘Grass, Gravel & Snow’, ‘Mud and Ruts’, ‘Sand’ or ‘Rock Crawl’. Similar systems of varying degrees are now widely used by Toyota, Jeep, Ford and others.