This Axial-Flux Motor With a PCB Stator Is Ripe for an Electrified World

The heart of any electric powered motor is made up of a rotor that revolves around a stationary section, called a stator. The stator, typically manufactured of iron, tends to be significant. Stator iron accounts for about two-thirds of the bodyweight of a regular motor. To lighten the stator, some individuals proposed producing it out of a printed circuit board.

Whilst the thought of changing a hunk of iron with a light-weight, ultrathin, quick-to-make, extended-lasting PCB was eye-catching from the outset, it didn’t gain popular adoption in its earliest programs inside of lawn equipment and wind turbines a very little above a 10 years ago. Now, although, the PCB stator is acquiring a new lease on life. Count on it to preserve bodyweight and hence electricity in just about anything that employs electric power to impart motive power.

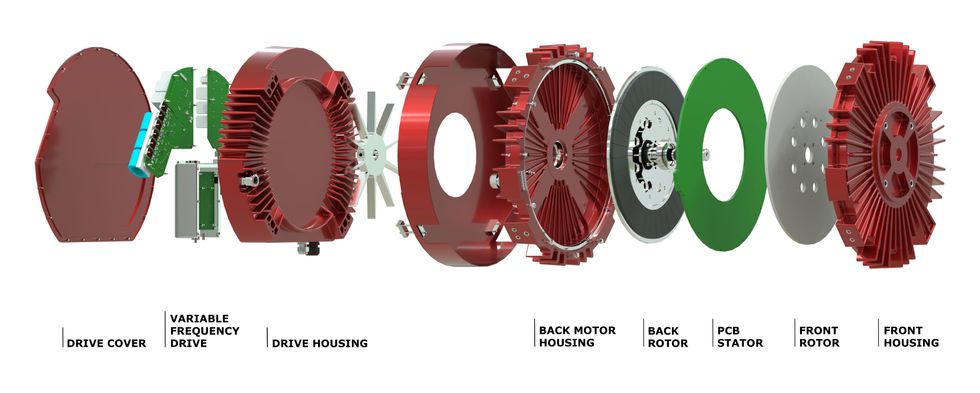

The layered elements of an Infinitum Electric axial-flux motor are revealed right here, in exploded form.INFINITUM Electric

This preserving of strength is critically important: Computer software may be taking in the world, but energy is progressively what helps make the world go round. Electrical motors consume

a small around half of the world’s electricity nowadays. Some 800 million motors are now sold annually around the globe, according to the market place research group Imarc, a amount that has been escalating by 10 percent each and every yr. Electrical motors are earning significant inroads into vehicles, trains, and aircraft, as effectively as industrial tools and heating, ventilating, and air-conditioning devices. Transportation, building, and HVAC jointly account for about 60 % of all U.S. greenhouse fuel emissions a lot more economical electrical motors will aid slice emissions in these sectors.

In spite of the rewards of the PCB stator, individuals had been sluggish to embrace the layout because of a couple of misconceptions.

Very first, there was the mistaken belief that PCBs were excellent only for fragile programs. But in 2011,

Main Out of doors Electrical power produced a leaf blower and a weed trimmer, both of which utilized a PCB stator and still ended up rugged as properly as silent.

2nd, there was a sense that PCB stators could be utilized only for minimal-ability machines. But in 2012 Boulder Wind Ability set a PCB stator in a

12-meter-diameter immediate-travel generator for a wind turbine that output 3 megawatts of electrical power and just over 2 million newton meters of torque. It was one particular of the smoothest-working substantial-power generators at any time created.

Neither corporation endured. Boulder Wind Electrical power ran out of funding right before it could safe commercial contracts. Core Outside Energy couldn’t contend in a crowded current market the place there had been much less expensive possibilities. However, their pioneering achievements demonstrated the feasibility of PCB stators.

Rapidly-ahead to now. My business,

Infinitum Electric, of Austin, Texas, has formulated a PCB stator motor that matches a extensive wide variety of reasons. Our motor generates as a lot electricity as a common alternating-existing induction motor but has half the body weight and dimensions, tends to make a fraction of the noise, and emits at least 25 percent much less carbon. It is now locating programs in HVAC, manufacturing, large marketplace, and electrical motor vehicles. Here’s how it performs.

The Infinitum Electric powered motor is what’s recognised as an axial-flux motor, a structure in which the stator’s electromagnetic wiring stands parallel to a disk-formed rotor made up of long term magnets. When alternating present flows as a result of, it can make the rotor spin. The motor also has an air core—that is, there is no iron to mediate the magnetic flux and nothing in between the motor’s magnetic elements but thin air. Put all these points together and the final result is an air-core axial-flux everlasting-magnet motor.

In the earlier, attempts to construct these types of a motor faced really serious useful hurdles. A sophisticated production course of action was required to establish the stator, the copper windings had been bulky, and the coil assist framework was intricate. As a end result, the air hole was so wide that only a sizeable magnet mass could generate the necessary magnetic flux.

At Infinitum Electric powered, we did absent with those copper windings and as an alternative use photolithographic methods to etch slim copper traces interleaved with epoxy-glass laminate, which insulates just about every coil from neighboring coils. Reducing the iron core and reducing copper jointly preserve 50 to 65 % of the body weight and 50 to 67 percent of the quantity of the motor, when when compared to an equivalent conventional iron-core motor. And conveniently, the copper and the laminate expand and contract similarly as the temperature rises and falls, averting strain that may well normally slowly and gradually pull the parts apart.

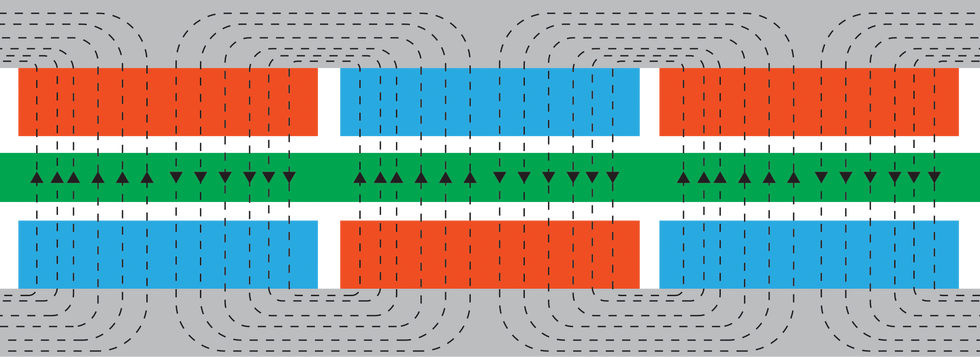

The absence of a stator core lets us to place two identical rotors dealing with every other on either side of the stator, with each rotor carrying highly effective long term magnets. This arrangement generates a continual magnetic flux. As in other axial-flux motors, that flux is parallel to the axis of rotation, fairly than radial. Since the magnetic air gap is slender, we need only a smaller magnet, which is why we can wring a lot of electric power from a specified mass and quantity.

Our motor generates as a lot electricity as a regular AC induction motor but has 50 % the fat and dimensions, helps make a fraction of the sounds, and emits at the very least 25 percent much less carbon.

What’s more, PCBs are produced by an automated procedure, which usually means they’re considerably far more uniform and dependable than hand-wound machines. We built them even much more reliable by simplifying their topology, which has to do with the motor’s phases.

An electrical period is an alternating voltage that types a sinusoidal wave that is shifted in time relative to the voltage in an additional section. The different phases are synchronized so that the sum of the currents is normally zero. When a multiphase voltage system is utilized to a motor that has a separate winding for just about every section, the circulation of many currents generates a magnetic industry that rotates in room. The conversation of this rotating subject and the field developed by rotor magnets is what turns the rotor.

Past PCB stators blended the copper traces from distinct phases in the similar layer, which developed the potential for shorter circuits. We as a substitute have each and every layer carry only a single electrical section, and we reduce the selection of connections amongst layers. That arrangement offers a steady route for the electrical recent and lessens the chance of electrical failures.

Another advantage of the new format is the freedom it presents designers to hook up coils possibly in collection or in parallel. Connecting the coils in sequence is suitable for three-section industrial purposes and upcoming-era electric automobiles. Connecting in parallel is far better for very low-voltage programs, these types of as in an auxiliary EV motor.

Like other long lasting-magnet motors, our axial-flux motor demands a variable frequency travel to effortlessly commence and accelerate the motor to the preferred pace. The VFD also controls the speed and torque as necessary by the software.

A brief path for magnetic flux is built possible by sandwiching rotors [gray] with magnets [red and blue] all around a thinly printed circuit board stator [green].

Having said that, the air-core style and design gives the motor exceptionally minimal impedance (usually just 5 to 7 percent as a lot as in a traditional iron-core motor), since air cannot consist of as much magnetic electricity as iron can. There is thus incredibly small magnetic vitality available to clean out the versions in the voltage provided to the motor by the VFD. To solution this deficiency, we added one more component: an built-in variable frequency generate that is high-quality-tuned to operate with a low-impedance motor. Our VFD works by using substantial-performance silicon carbide MOSFETs, which decrease losses and contribute to in general technique performance.

The VFD also screens general performance, and the effects can be described by using the cloud, if the person needs. The motor’s program can also be up to date in this style. These distant checking gives a wide range of ways to conserve electricity, manage efficiency, and forecast when servicing might be desired.

The thinness of the PCB furnishes a higher surface-to-quantity ratio, which helps make for more productive cooling, consequently making it possible for us to force two to a few times as significantly current for a supplied total of copper. The cooling can be accomplished by blowing air in excess of fins on the outside of the motor and across the electronic compartments.

Removing the iron main removes loss due to the cyclical magnetization and demagnetization of the iron, though also steering clear of strength-throwing away eddy currents in the steel. Our air-main motor can as a result operate at a substantial performance around masses ranging from 25 % to 100 percent of the rated power. Skipping the iron main also implies the magnets on the rotors facial area a continuous reluctance and a constant magnetic area as the rotor turns. This arrangement removes eddy-latest losses in the magnets and the rotors, which as a result can be built of standard, unlaminated, small-carbon steel plates.

In a typical electric motor, the two the stator and rotor are produced of ferromagnetic products. After electrical currents are utilized and rotating magnetic fields are proven, these fields make two forces: a person that generates practical torque and results in the rotor to rotate, and another that pulls the rotor radially to the stator. This radial drive does absolutely nothing useful, and it aggravates sound and vibration, for the reason that the slots in the stator—needed to accommodate the copper coils—generate pulses.

Here’s why that occurs: A magnetic flux provides a pressure that at initial details in the similar path the rotor is going in then, as the rotor turns, the alignment of the rotor poles improvements in relation to the stator slots right up until the drive points in the opposite way. This alternating drive creates torque ripples, which can bring about metal tiredness in the motor and in the equipment that it is driving.

But there is no this kind of alternating magnetic drive in the Infinitum motor. This edge, together with other efficiencies, is why its sound averages about 5 decibels decrease than that of traditional motors. That may well not seem to be like a lot of a reduction, but this element of motor noise tends to be at a significantly bothersome pitch.

By combining the lightness of an air-core motor with the high torque density of an axial-flux equipment, the Infinitum motor is perfectly suited for developing air flow and HVAC devices. Which is particularly helpful now that the pandemic has place a precedence on purifying indoor air. Warmth pumps, which warmth and neat in just one system, are a further application in which the motor can conserve electricity, relieve installation, and decrease noise. In accordance to

latest assessments performed by the U.S. General Solutions Administration and the U.S. Division of Strength, Infinitum Electric powered motors could help you save up to US $8 million per year if deployed in the GSA’s HVAC vegetation.

Electric automobiles are an additional massive market place for this new motor. EVs are projected to make up 31 % of the world fleet by 2050, in accordance to the

U.S. Vitality Information and facts Administration.

Our organization is functioning with a major automotive provider to create an oil-cooled motor for a very long-vary hybrid motor vehicle. Oil cooling works much much more efficiently in our style and design than in a common motor since the coolant can be easily applied to the complete floor of the PCB. With oil cooling, we have understood a threefold maximize in electricity density over our possess air-cooled motor, bringing the ability density into the 8 kilowatt/kilogram to 12 kW/kg variety. That helps make the oil-cooled version suitable for use in electrical aviation, another promising market place.

We’re also performing with corporations that specialize in product managing, such as forklifts, conveyor devices, and the mixing products that’s used to make food items and beverages.

Caterpillar Undertaking Cash has invested in Infinitum Electrical to build a new line of alternators that are just one-3rd the measurement and weight of current styles and quieter and a lot more efficient as nicely. The alternator marketplace is approximated at $17 billion a year and increasing.

We estimate that if each individual motor in the planet had been changed by an Infinitum Electrical motor, it would decrease carbon emissions by 860 million tonnes for each calendar year. That’s the equal of eradicating the emissions from 200 million autos each year. As motors grow to be ubiquitous, even smaller enhancements in effectiveness have the electricity to make a big difference for our planet these days and about the up coming century.

This post appears in the April 2022 print difficulty as “This Axial-Flux Motor With a PCB Stator Is Ripe for an Electrified Earth.”

From Your Web-site Posts

Linked Content articles All over the Web